Common Airbus & Safran Helicopter Maintenance Issues (and How We Fix Them)

Common Airbus & Safran Helicopter Maintenance Issues (and How We Fix Them)

Maintaining Airbus and Safran-powered helicopters requires a high level of technical expertise, attention to detail, and FAA-certified processes. From the rugged AS350 B3 to the advanced EC130 T2, operators across the Southwest rely on these aircraft for charter, utility, and public safety missions. But even the most reliable helicopters encounter recurring issues that, if left unresolved, can impact performance, safety, and compliance.

At Black Mountain Aviation, we specialize in Airbus helicopter maintenance and Safran engine repair from our FAA-certified facility in Boulder City, Nevada. This article outlines the most common issues encountered on these aircraft—and how our expert team solves them quickly, safely, and by the book.

1. Arriel Engine Module Failures

Common Issues:

- Hot section distress (Modules 3, 4, or 5)

- Oil leaks and cracked seals on

Module 2B

- Fuel control malfunctions in HMUs (Hydromechanical Units)

- Freewheel shaft wear or misalignment

These problems are common in Safran Arriel 1D1, 2B, and 2B1 engines, especially under high-usage environments like aerial tour operations or firefighting.

How We Fix It:

- Our technicians inspect each engine using Safran-approved procedures and borescope analysis.

- We stock

overhaul-exchange modules for fast replacement, including:

- Module 1: 70BM012000

- Module 3: 70BM032020

- Freewheel Shaft Assembly: 0292900020

- Each repair is logged and certified per FAA requirements, using

OEM or PMA-approved parts.

We also offer field support for engines removed in remote areas, a major benefit for operators across Nevada, Utah, and the Southwest.

2. Rotor System Vibration or Instability

Common Issues:

- Excessive play in tail rotor spiders or pitch change units

- Worn AVA (anti-vibration assemblies) causing resonance at certain RPMs

- Cracked or deformed swashplates, especially on EC130s

These symptoms lead to increased pilot fatigue, decreased control responsiveness, and long-term airframe stress.

How We Fix It:

We stock and service high-failure rotor system parts including:

- Tail Rotor Spiders: 350A33-2030-00, 350A33-2167-00

- Swashplates: 350A37-1004-10, 350A37-1004-11

- AVA Assemblies: 350A31-0033-02 through 350A31-0033-06

Our overhaul and exchange program for high-wear items reduces downtime and ensures all rotor components meet factory tolerances and dynamic balance requirements.

3. Bevel and Epicyclic Gearbox Damage

Common Issues:

- Bevel gear scoring or gear lash

- Epicyclic reduction gear wear due to high torque or poor lubrication

- Improper maintenance of MGB/gearbox filters

These are critical systems that affect lift and tail rotor input, making proactive service non-negotiable.

How We Fix It:

We perform precision inspections of:

- Epicyclic reduction gearboxes: 350A32-0120-00

- Bevel gear assemblies: 350A32-0350-02M

We use a combination of factory measurement specs, endoscope inspections, and magnetic particle testing to identify fatigue or stress cracks before they evolve into flight-critical failures.

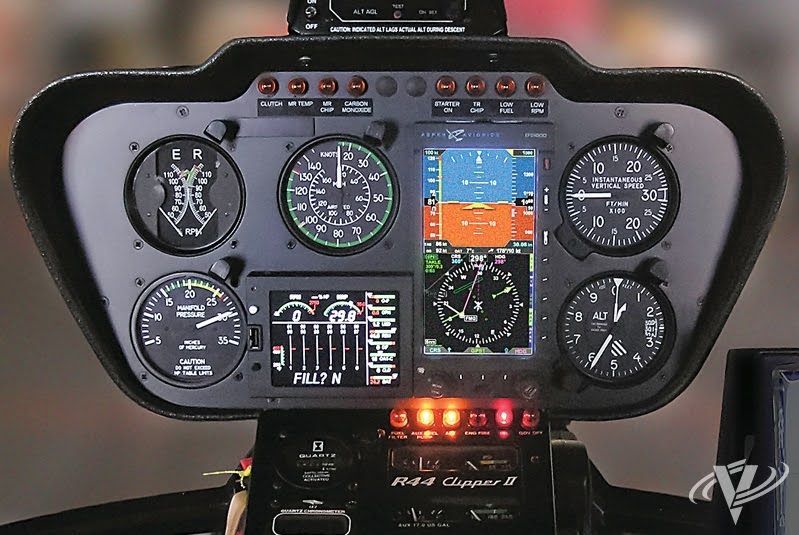

4. Avionics Malfunctions and Certification Issues

Common Issues:

- Transponder test failures under FAR 91.413/91.227

- ELT battery expiration or test failure under 91.207

- IFR pitot-static system drift or blockage

- Outdated or non-compliant ADS-B systems

Many Airbus helicopters have legacy avionics platforms not compliant with current FAA requirements or operator needs.

How We Fix It:

As a certified

avionics installation and repair facility, we offer:

- 91.411 and 91.413 IFR/VFR testing and certifications

- ADS-B Out installation and troubleshooting

- Replacement of legacy systems with Garmin, BendixKing, or Avidyne solutions

Our avionics shop also performs on-site certifications to keep your aircraft compliant without unnecessary downtime.

5. Poor Recordkeeping or Missing Compliance Logs

Common Issues:

- Missing component times

- Gaps in maintenance tracking

- Improper FAA documentation for inspections or AD compliance

Even when maintenance is performed, lack of records can ground an aircraft during an audit or resale.

How We Fix It:

Black Mountain Aviation ensures:

- Digital and physical records of all services performed

- FAA Form 8130-3 issuance for major components

- AD research and compliance tracking tied to aircraft serial number

We can also assist in rebuilding maintenance records for aircraft that have been serviced elsewhere with incomplete logs.

6. Hard-to-Find Replacement Parts for Airbus Helicopters

Common Issues:

- Long lead times for Arriel modules or rotor components

- OEM backorders for swashplates, spiders, or tail gearboxes

- Limited U.S. stock for EC130 T2-specific parts

How We Fix It:

We maintain one of the

most comprehensive inventories in the region, including:

- Arriel 1D1 and 2B1 engine modules

- Crossbeams and bidirectional suspension bars

- Overhaul-exchange stock for swashplates and tail rotor components

What Sets Black Mountain Aviation Apart?

At our FAA-certified repair station (LVBR789X), we don’t just fix helicopters—we solve problems that impact your mission, operations, and safety record. Our strengths include:

- Over

250 combined years of technician experience

- Airbus and Safran specialists trained on ASTAR, EC130, and Arriel 1D1/2B/2B1

- An on-site avionics shop fully certified for installation, inspection, and upgrade services

- A massive inventory of in-demand parts for quick turnaround

- Strategic location at

Boulder City Municipal Airport (KBVU) with full FBO support

Our team includes certified A&P/IAs with experience from the US Forest Service, military rotorcraft repair, and OEM-specific training programs. We understand the nuances of your aircraft and deliver repairs that meet or exceed factory specs.

Who We Serve

Our typical clients include:

- Tour operators running Airbus H125s and EC130s

- Government and contract rotorcraft missions

- Charter operators flying under Part 135

- Private helicopter owners and aviation businesses in Nevada, Utah, and the Southwest

Final Thoughts

Common maintenance issues in Airbus and Safran helicopters may be predictable—but their impact doesn’t have to be. From engine module wear and gearbox inspection to avionics upgrades and rotor system replacements, our team delivers high-caliber solutions with a service-first mindset.

If you're looking for a reliable, FAA-certified partner who understands your aircraft down to the part number, trust Black Mountain Aviation to keep you flight-ready.

Contact us at (702) 294-1044 or visitbmaviation.net to schedule a consultation or request a parts quote.