How to Choose the Right Aircraft Repair Station in Nevada

How to Choose the Right Aircraft Repair Station in Nevada

Choosing the right aircraft repair station is one of the most important decisions any aircraft owner or operator can make. Your aircraft represents safety, operational reliability, financial investment, and in many cases your ability to complete essential missions. Whether you operate a helicopter, a private aircraft, or a commercial fleet, the quality of your maintenance partner directly influences everything from performance to regulatory compliance.

If you are based in Nevada or fly frequently through the Southwest, it helps to understand what separates a trustworthy maintenance provider from one that may not meet FAA standards. This guide is designed to help you make a confident and well informed decision about choosing the right aircraft repair station in Nevada.

Why the Choice of Repair Station Matters

Aircraft maintenance is highly regulated for a reason. Every inspection, repair, and installation affects the safety of the aircraft and the people who fly on it. A reliable repair station not only keeps your aircraft airworthy but also protects you from compliance issues, operational delays, and preventable failures.

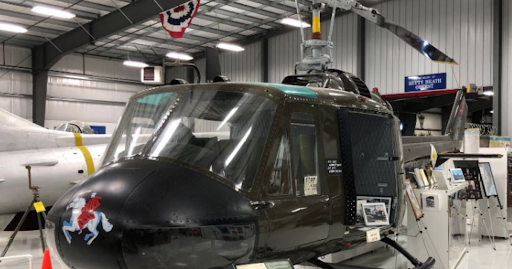

Nevada has a unique aviation environment that requires experienced and certified professionals. High heat, desert conditions, tourism flight volume, and demanding rotorcraft missions all contribute to the need for specialized maintenance expertise. Choosing the right aircraft repair station can ensure your aircraft performs safely and consistently in these conditions.

1. Look for FAA Part 145 Certification

One of the most important factors when choosing an aircraft repair station in Nevada is FAA Part 145 Certification. Part 145 Repair Stations are authorized by the Federal Aviation Administration to perform regulated aircraft maintenance, including inspections, repairs, avionics installation, engine servicing, and component work.

FAA certified repair stations must meet strict requirements involving:

- Technician qualifications

- Tooling and calibration

- Quality control systems

- Oversight and documentation

- Facility standards

- Approved procedures and workflows

If you want a repair provider who follows consistent and legally compliant processes, choosing a Part 145 Repair Station is essential.

2. Ensure the Facility Has Experience With Your Aircraft Type

Not all repair stations service all aircraft. Nevada operators frequently fly Airbus H125, AS350, EC130, Bell 206, Bell 407, and MD 500 rotorcraft in addition to a variety of fixed wing aircraft. It is important to confirm that the repair station has proven experience with your specific platform.

Ask about:

- Factory training

- Model specific tooling

- Maintenance history on your aircraft type

- Familiarity with dynamic components

- Experience with Safran Arriel engines or other major powerplants

A station that regularly services your aircraft type will complete work more efficiently, more accurately, and with a deeper understanding of mission specific needs.

3. Evaluate the Station’s Avionics Capabilities

Avionics play an increasingly important role in aircraft safety and performance. Modern systems require knowledgeable technicians who understand both the hardware and the FAA testing requirements. A strong avionics shop should offer:

- Avionics installation services

- GPS and navigation upgrades

- ADSB and transponder testing under 91.413

- ELT testing under 91.207

- IFR certification under 91.411 and 91.413

- Troubleshooting and wiring repairs

- Garmin, BendixKing, and Avidyne support

If your operations rely on advanced avionics or regular IFR flying, choosing a repair station with certified avionics capabilities is essential.

4. Check for Rotorcraft and Component Expertise

Nevada’s helicopter community is large and active, especially in tourism, utility work, firefighting, government operations, and private ownership. Because helicopter components have unique maintenance demands, your repair station should have experience with:

- Rotor systems and dynamic components

- Transmission and MGB servicing

- Epicyclic gearboxes

- Tail rotor spiders

- Swashplates and AVA units

- Structural repair

- Safran engine modules and components

This type of specialized knowledge is critical for maintaining safe and reliable rotorcraft operations.

5. Look for Transparent Processes and Strong Communication

A reliable repair station will always:

- Communicate clearly

- Explain repairs before starting work

- Provide accurate estimates

- Document all procedures

- Maintain transparent logbook entries

- Share inspection findings

- Respond quickly to customer questions

Good communication is a sign that the repair station values your aircraft and your trust. When maintenance providers prioritize clarity and customer service, you experience fewer surprises and a smoother maintenance process.

6. Ask About Turnaround Times and Scheduling Availability

Nevada’s aviation market is busy. With tourism flights in Las Vegas, charter operations, flight schools, and private owners all competing for service slots, availability matters.

Ask questions such as:

- How far in advance do I need to schedule?

- What is the expected turnaround time for inspections or repairs?

- Do you offer field support or mobile maintenance?

- Do you stock common parts for my aircraft?

- Can you support AOG situations?

A repair station that plans well, communicates clearly, and maintains efficient workflow can help you minimize downtime and stay mission ready.

7. Review Their Track Record and Reputation

A strong repair station will have:

- A history of safe operation

- Long term customers

- Skilled technicians with decades of experience

- Positive feedback from operators

- Membership in reputable aviation associations

FAA Part 145 Repair Stations such as Black Mountain Aviation in Boulder City often employ technicians with significant backgrounds in Airbus and Bell platforms, avionics testing, Safran engine service, and Part 135 fleet support. Experience of this depth helps ensure that your aircraft receives care rooted in proven knowledge and professionalism.

8. Confirm That Documentation and Traceability Are Prioritized

Proper documentation protects your aircraft and ensures continued airworthiness. Ask the repair station how they handle:

- Logbook and inspection entries

- Part traceability

- Airworthiness release documentation

- Component lifecycle tracking

- Warranty records

When documentation is thorough and precise, you benefit from higher resale value, easier troubleshooting, and stronger regulatory compliance.

Clear Answers to Common Questions

What is the best way to choose an aircraft repair station in Nevada

Look for FAA Part 145 certification, aircraft specific expertise, and strong communication practices.

Do all aircraft repair stations service helicopters

No. Choose a station with rotorcraft experience and proper tooling.

Why is Part 145 certification important

It ensures the maintenance provider follows FAA approved processes designed to protect your aircraft.

How can I tell if a repair station is qualified

Check certifications, technician experience, and their history servicing your type of aircraft.

Final Thoughts

Choosing the right aircraft repair station in Nevada is one of the most meaningful decisions you can make for your aircraft and your safety. When you find a provider that combines FAA certification, technical expertise, clear communication, and a commitment to quality, you gain a trusted partner who supports you in every mission.

With the right repair station by your side, your aircraft remains reliable, compliant, and ready for whatever the skies bring next.

avionics installation services

aircraft maintenance services

schedule your maintenance appointment

Safran and Airbus component inventory