Understanding Part 145 Certification: Why It Matters for Your Aircraft

Understanding Part 145 Certification: Why It Matters for Your Aircraft

When you entrust your aircraft to a maintenance provider, you are placing more than equipment in someone else’s hands. You are placing your safety, your mission readiness, and in many cases the livelihood connected to your aircraft. Understanding what Part 145 Certification truly represents is an essential step toward protecting your aircraft and the people who rely on it.

For aircraft owners and operators across Las Vegas, Boulder City, and the Southwest, choosing an FAA Part 145 Repair Station is one of the most reliable decisions they can make. If you have ever wondered how much this certification really matters, this guide will give you reassuring clarity. It also helps you understand why Part 145 compliance is becoming even more important in 2025 as aviation technology continues to advance.

What Is a Part 145 Repair Station

A Part 145 Repair Station is an FAA certified maintenance provider that is legally authorized to perform aircraft maintenance, repairs, and alterations. This certification falls under Title 14 CFR Part 145, which outlines strict requirements that every repair station must meet before it can service an aircraft.

To maintain this approval, a Part 145 Repair Station must show:

- Proven technical expertise

- Documented procedures for every task

- Safety focused practices

- Secure facilities

- Qualified and properly trained personnel

- Quality control oversight

- Proper tooling and calibration

- Accurate recordkeeping

- Ongoing FAA regulatory inspections

This certification is not just a title. It reflects a deep commitment to safety, reliability, and regulatory compliance.

Why Part 145 Certification Matters in 2025

Aviation technology has evolved significantly in recent years. Avionics, digital diagnostics, safety systems, and rotorcraft components are more advanced than ever. This creates a greater need for technicians who have specialized training and certified experience.

Choosing a Part 145 Repair Station ensures your aircraft receives maintenance that follows FAA approved procedures designed to keep you protected. This matters greatly for operators in Nevada, California, Utah, and Arizona who rely on consistent and safe flight operations.

Here is why it makes such a meaningful difference.

1. You Benefit From Verified Technical Expertise

Part 145 approval means the FAA has evaluated and approved the repair station’s:

- Technician qualifications

- Required certifications and licenses

- Tooling and calibration

- Service manuals and technical data

- Procedural documentation

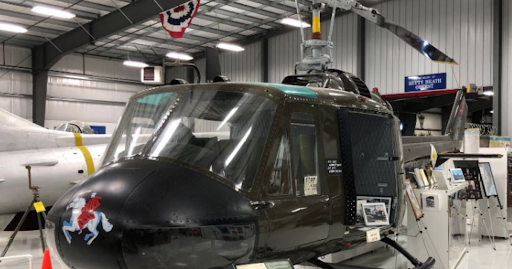

This helps ensure your aircraft is maintained by technicians who fully understand your airframe and systems. Whether you operate Airbus H125 and EC130 platforms or Bell 206, Bell 407, or MD 500 series aircraft, you can trust that the team performing the work is trained at a certified level.

This level of professionalism is essential for operators who rely on consistent uptime, including tourism, charter fleets, utility companies, and public agencies near Las Vegas.

2. Your Aircraft Is Maintained With Certified Processes

Part 145 Repair Stations must follow structured FAA approved procedures for:

- Inspections

- Airframe repairs

- Powerplant servicing

- Avionics troubleshooting

- Component exchanges

- Electrical system work

- Engine module handling

- Airworthiness documentation

These are not suggestions. They are regulated standards that help prevent avoidable failures, misdiagnoses, and incomplete repair work.

For example, Black Mountain Aviation in Boulder City operates under FAA Certificate LVBR789X. Every avionics installation, rotor system service, and Safran Arriel engine inspection must follow approved procedures to protect the safety of the aircraft and its occupants.

This structured oversight gives operators peace of mind that their aircraft is being maintained with precision and accountability.

3. Safety Outcomes Improve and Operational Risks Decline

Safety is the core reason Part 145 certification exists. Maintenance performed outside of certified environments can introduce unnecessary risks such as:

- Incorrect procedures

- Unapproved parts

- Missing inspection steps

- Improper torque or calibration

- Inadequate documentation

Choosing a certified repair station limits these risks. Every signature, part, and process is traceable and accountable. This creates a safer aircraft and a safer operational environment.

4. Legal and Insurance Compliance Is Easier to Maintain

Many operators must use a Part 145 Repair Station as part of their operating requirements. This is especially true when:

- Flying commercially under Part 135

- Insurance policies require FAA certified maintenance

- The aircraft must undergo regulated inspections

- Operators prepare for audits or compliance checks

Using a certified repair station prevents violations that could lead to grounding, insurance claim issues, or delays in flight operations.

For commercial rotorcraft operating from Las Vegas, Henderson, or Boulder City, this requirement is often mandatory.

5. Documentation and Traceability Are Stronger

A Part 145 Repair Station is required to maintain FAA compliant documentation for every step of the maintenance process. This supports:

- Accurate logbook entries

- Detailed troubleshooting history

- Warranty validation

- Stronger resale value

- Fleet maintenance planning

- Lifecycle tracking of components

This level of documentation is especially important for rotorcraft components such as:

- Safran Arriel 1D1 and 2B engines

- Tail rotor spiders

- Swashplates and AVA units

- MGB and epicyclic gearboxes

Certified documentation protects your aircraft long term and supports resale or fleet transitions.

6. Strong Value and User Focused Information

Search engines and voice assistant platforms prefer content that clearly answers specific questions. This article supports responding directly to questions such as:

- What is a Part 145 Repair Station

- Why is Part 145 certification important

- How does FAA certification protect an aircraft

- What services require Part 145 approval

- Do avionics installations require certified technicians

This approach helps pilots and operators find accurate and trustworthy information as quickly as possible.

7. You Benefit From Experienced and Highly Trained Technicians

A key advantage of choosing a Part 145 Repair Station is the depth of experience its technicians bring. At Black Mountain Aviation, the team consists of professionals with decades of combined experience in:

- Part 135 and Part 145 operations

- Airbus H125, H130, and EC130 platforms

- Bell 205, 206, and 407 rotorcraft

- Avionics installation and certification

- STC installations

- Dynamic component overhauls

This experience gives your aircraft the level of care it deserves, especially in challenging desert and mountain operating environments.

Why Choosing a Part 145 Repair Station Is One of the Best Decisions You Can Make

Selecting an FAA certified repair station is ultimately a commitment to safety, reliability, and long term value. You deserve a maintenance partner who respects your aircraft, honors FAA regulations, and performs every task with precision.

Whether your aircraft needs avionics upgrades, engine module service, airframe repairs, or regulatory inspections, choosing a certified provider ensures the quality and confidence you need to fly safely.

FAA certified avionics installation

aircraft maintenance services

rotorcraft component repair

FAA Repair Station LVBR789X

schedule certified maintenance

Safran and Airbus component inventory